Neon Signs – Schaefer Photography Camera Sign

It’s a dream for many people to see their name in the bright big city lights – whether in the streets of New York or on the Las Vegas strip – beautiful neon signs remind us of the good ol’ times from the 1920s to the 1960s. That was the heyday of neon. Scott has always been a lover of the bright and beautiful colors that come from neon signs. When we first started Schaefer Photography we thought it would be cool to have our logo made out of real glass neon tubes and not the new LED lights that some mistakenly claim to be neon. We wanted the real deal that takes an experienced artist to make. Luckily, we have one such artist located right here in Columbia, Mo.

Meet the Glass Bender Who Creates Neon Signs

Jim McCarter and his wife Becky own and operate Creative Neon. McCarter has worked as a neon glass bender for more than 40 years. Jim has worked on or created many of the neon signs around Columbia, Mo. When he and Becky started dating in the 1970’s, Jim started apprenticing under Becky’s grandfather who had learned the neon sign trade for her father’s sign business in Waterloo, Iowa. Jim enjoys a challenge and loves helping keep the past alive by fixing old neon signs and creating new ones like ours! It takes a lot of skill, patience and artistry to bring a sign to life.

The Neon Sign Making Process

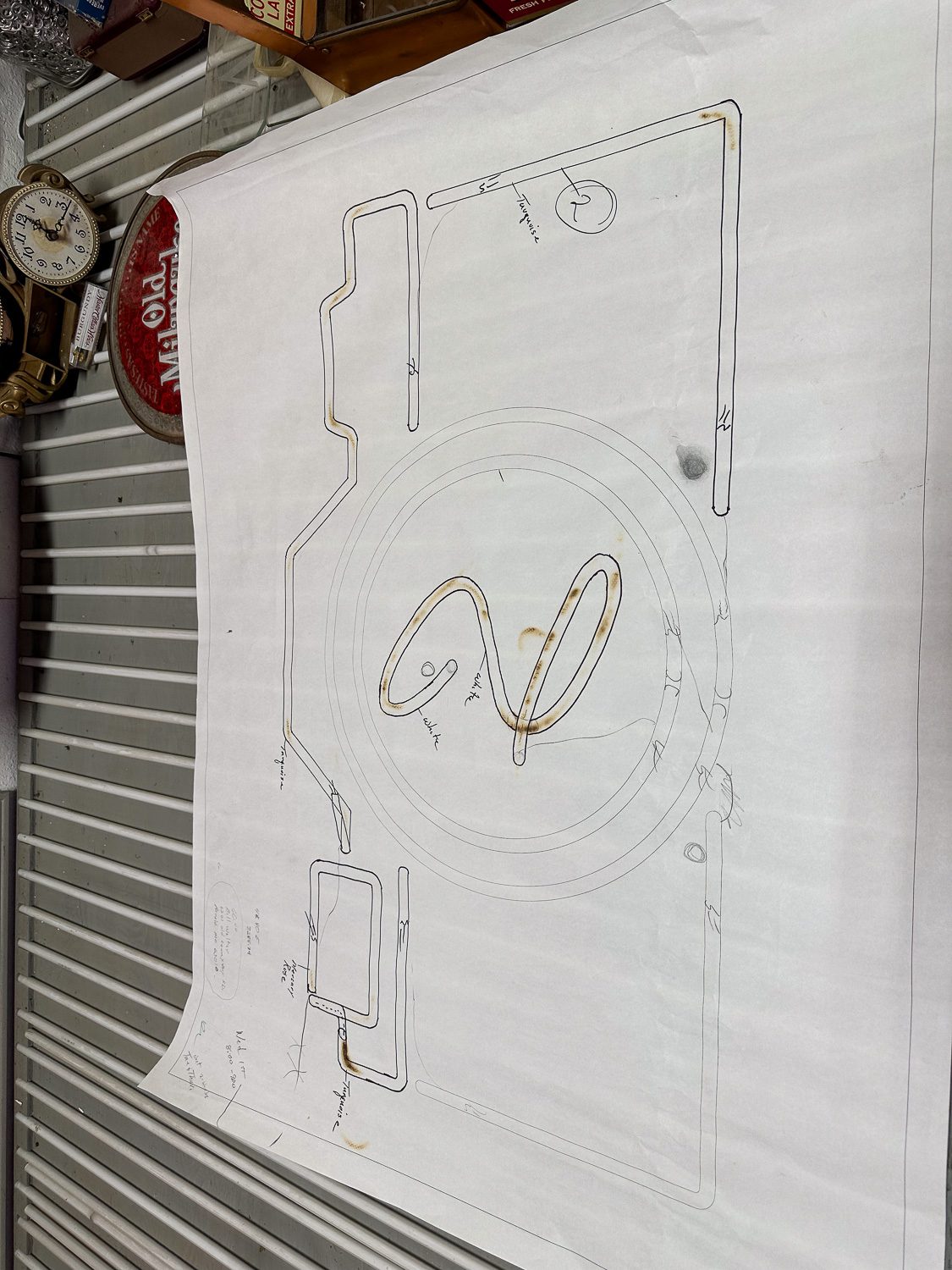

All neon signs start with a design or pattern. Originally we thought about creating a sign with just our S logo but a few years went by and one day we saw a vintage camera store sign in a photo online and decided we could merge the two ideas into one! We picked the colors of our sign while watching Disney Pixar’s Cars movie with the kids. During one scene where Lightning McQueen helps Radiator Springs turn its neon lights back on and Flo’s V8 Cafe lit up – we loved the vintage vibe of the turquoise and pink lights! The colors are important to the process because the colors are created by filling the tube with either neon or argon gas. Some tubes have a coating inside that affect the color by altering the wavelength of the emitted light to create specific colors. The tubes appear white when the sign is turned off.

Several factors influence the color emitted by neon signs. Temperature and pressure play a role in determining the shade and intensity of the light produced. Additionally, the composition of gases used and the amount of electrical current passing through the tube contribute to color variation.

All The Details

Once the pattern is complete and colors are chosen – it’s time to bend some glass! Jim heats the glass tubing over an open flame using either a crossfire or a ribbon burner — which are somewhere between 1,800 and 2,000 degrees. Electrodes need to be attached to the ends of the tube to seal the tubes and allow for electricity to pass through. After heating part of the tube for three or four minutes, Jim has about 30 seconds to bend the glass and set it on the pattern.

The glass is bent in small sections so the glass doesn’t bend in unexpected directions. While heating the glass, he keeps constant puffs of air flowing into the tube by blowing through a silicone straw so the tube doesn’t collapse and then artistically bends the glass tube to mirror the pattern. All letters are created backwards so once they are connected to electricity and hooked up the sign they appear correctly with all the connections behind the letters.

Processing Neon Tubes

Once each individual piece of glass is created and cooled down, put the tubes under a vacuum, which draws out all the moisture and dirt. He then hook the tubes up to a bombarding transformer with lines that run above his table to heat up the glass to nearly 500 degrees. That cleans the glass and makes a vacuum inside the tube. He places small sheets between bends to make sure the glass doesn’t melt to itself. After the tube cools back down, he injects either neon or argon gas into it.

In a clear tube, neon gas will be red and argon will be blue. With the powder-coated tubes you can get other colors. A green powder-coated tube with red gas in it will light up orange. But if blue gas is added, it’ll light up green.

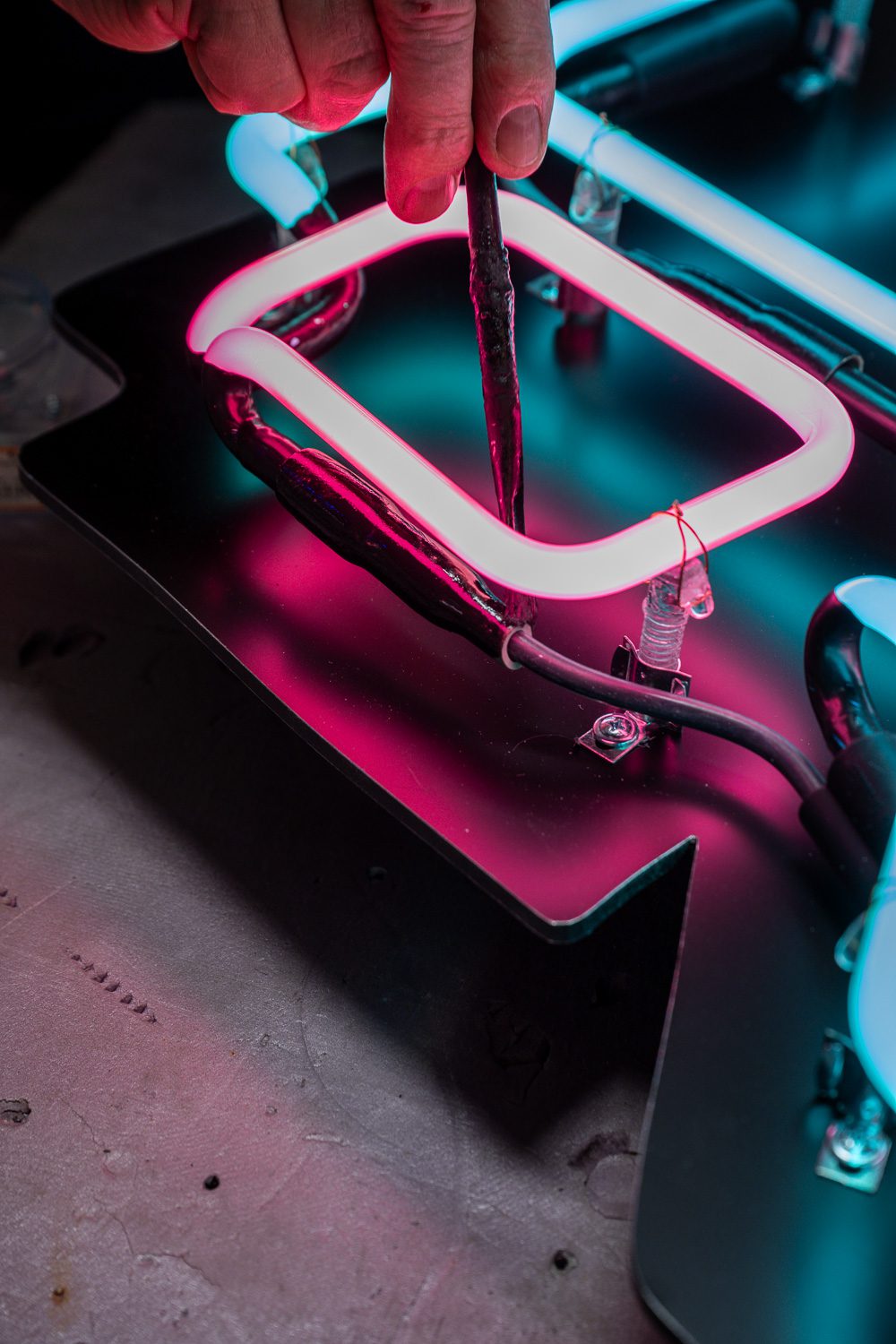

Blockout Painting

Next is the blockout painting process. Bending a neon tube is like writing without being able to pick up the pen from the paper, and blocking out is how glass benders hide the connecting elements. A special paint is brushed on to hide the light in any areas that Jim doesn’t want people to see.

Lighting Up The Neon Sign

Once all those steps are complete, the piece of the Schaefer Photography neon camera sign are laid out onto the sign background. Each section is mounted to a spacer with a copper wire which holds the sign in place and each piece is connected with wire for the electricity to flow through each section of the neon sign. A transformer is attached to the back of the sign and then it’s ready to light up!!